| PURPOSES OF THIS MANUAL |

The model CTL-618EVS series machine is built for easy and safe

operation and excellent manufacturing of work in process. The machine

is built with high quality material, and carefully to exacting standards

that guarantee the life, economical use, accuracy, and minimum maintenance

of the machine.

This manual is an introduction to the CYCLEMATIC model CTL-618EVS

HIGH ACCURACY TOOL ROOM LATHE. It is used for installation, operation

and maintenance of the CTL-618EVS CYCLEMATIC MACHINES.

Also, for fast reference, because it is necessary to make minor

adjustments or do preventive maintenance. (For personnel and operators

who deal with the CTL-618EVS machine.)

FOR MODEL CTL-618EVS EQUIPPED WITH ELECTRONIC VARI-SPEED SYSTEM |

|

CTL-618EVS |

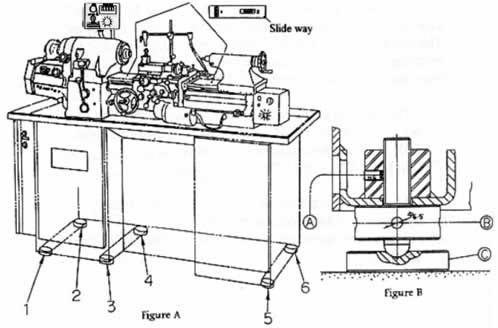

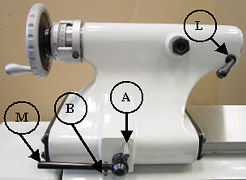

Levelling

- Put pads C (Fig.B) under each of six points.

- Loose set screw A (Fig.B)

- Insert a pin wrench into the hole B. Raise or lower by turning

(C.W.or .C.W)

- Tighten set screw A (Fig.B) to lock.

- Be sure every point is touching the ground to support the machine.

|

|

Lifting |

Figure 1 – Lifting machine

|

| Lifting machine, arrange rope or cable as shown in figure 1, and

check to see if the correct balance has been obtained. Then insert

pads of soft cloth between the edges of the rope and machine. The

net weight of this machine is approx 1050 kgs (2300 lbs). So the

rope or cable must be rated at 3000 lbs capacity. |

|

| A). INSPECTION AND CLEANING MACHINE |

An inspection should be made after arrival of the machine in your

plant. Look for possible damage caused by shock or vibration during

transportation, also check for any missing parts, standard tools

or other equipment.

In shipment, all exposed surfaces of the machine are coated with

a antirust liquid. Before moving carriage and cross-slide, leadscrew

tailstock…etc, these surfaces should be thoroughly cleaned to remove

all antirust liquid use a soft brush and solvent. This is very important

because it can prevent any dirt or grit which may have accumulated

on the antirust liquid from working under the sliding members and

causing undue wear.

※ CAUTION :

DO NOT USE COMPRESSED AIR TO CLEAN, WHICH WILL REDUCE THE MACHINES

LIFE. |

|

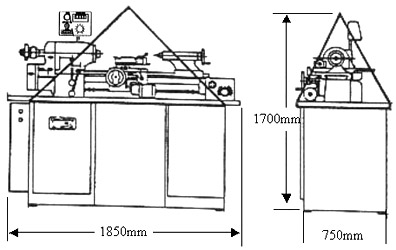

| A fairly flat foundation and proper installation will provide the

machine long-term high accuracy, so supplying a good solid foundation

of proper thickness is important. (Generally , a thickness of 300mm

(12”) is considered to be enough.) The machine has six adjustable

feet on the coners of the pedestal base, used for leveling the machine.

Place the pads under the feet of pedestal. To adjust, loosen the

set screw and raise or lower the foot with a pin wrench so that

all six feet rest firmly on the floor. When the adjustment is done,

tighten set screws. |

|

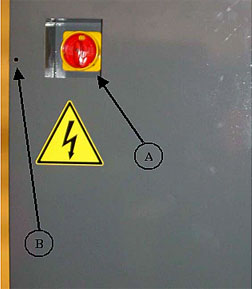

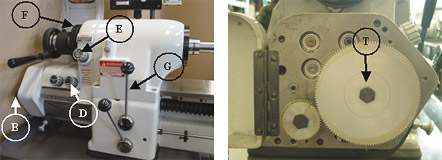

| The CTL-618EVS TOOLROOM LATHE is shipped completely wired and

assembled, Turn Cam Switch “A” (Figure 2) to the “OFF” position,

then check motor voltage. Loosen screws “B” (Figure 2), and open

the switch case cover, connect the wires from the power source to

the terminals (R.S.T), and ground connection is made at the “G”

(Figure 3) which is the electric switch case. |

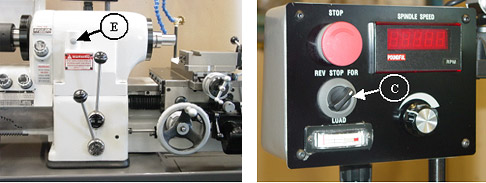

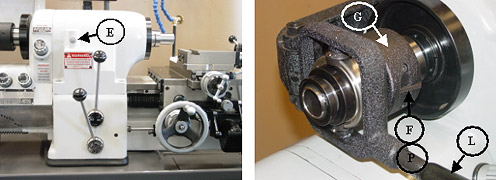

| Pull out Spindle locking Pin “E” (Figure 4), turn “C” (Figure 5)

in forward position. The spindle should rotate counterclockwise

when viewed from the tailstock end of the machine. If the spindle

dose not turn in the correct direction, turn Cam Switch “A” (Figure

2) to “OFF” position. Disconnect electric power source, and interchanges

any two leads until the turning direction is correct. When the spindle

is rotation correctly, secure switch case cover, turn Cam Switch

“A” (Figure 2) to “ON” position. |

|

| Figure 2-Control Unit Door |

Figure 3-Control Unit |

|

| Figure 4-Control Speed and Direction |

Figure 5-Speed Control Box |

|

※ CAUTION :

RUNNING THE MACHINE IN THE WRONG DIRECTION WILL RESULT IN DAMAGE TO

THE SPINDLE SPEED CHANGE UNIT. |

|

| D). LUBRICATION |

| Proper lubrication supplied carefully , will maintain the life

and performance of the machine for a long period. Therefore, lubricate

the machine with a high quality lubricant, and check periodically

to assure that the lubricant in the oil sight gage is filled to

the proper level. |

1. CARRIAGE LUBRICATION

Fill with Mobil Vactra Oil No.2 or equivalent in oil reservoir.

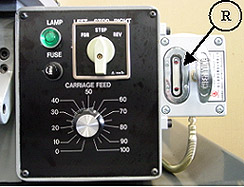

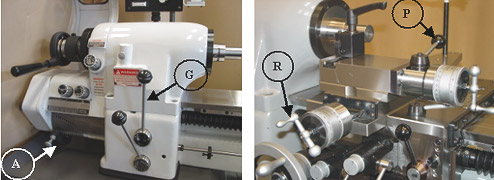

Lift plunger on reservoir "R" (Figure 6) hold briefly

and release to keep bed ways lubricated.

2. GEAR BOX AND CLUTCH LUBRICATION

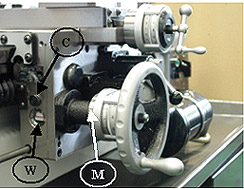

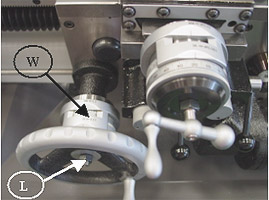

Maintain oil level in sight windows "W" (Figure 8). To

fill gearbox, remove plug "C"(Figure 8) use Automatic

Transmission Fluid Mobil 200 (Esso ATF or equivalent Change oil

every 500 hours.)

To drain oil, remove the Drain Plug "M" located under

the oil gear box (Figure 8).

※CAUTION:USE OF ANY OTHER TYPE OF OIL IN THE GEARBOX MAY RESULT

IN DAMAGE TO THE CLUTCH SURFACES. 3. HEADSTOCK LUBRICATION

The headstock spindle is mounted on precision preloaded ball, bearings.

The ball bearings are grease packed for life and require no further

lubrication.

|

Figure 6-Speed Change Unit

Figure 8-Gear Box Lubrication |

|

E). SPINDLE CONTROL LEVERS |

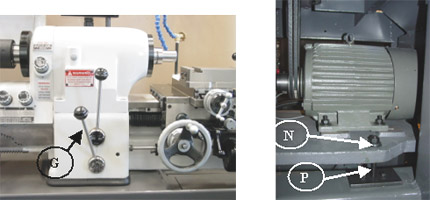

| To change spindle speeds. Push start button (D) Figure (9). Turn

cam switch (C) Figure (11) to the forward or reverse position and

move lever (G) Figure (10) to the start position. Turn cam switch

(I) Figure (11) to the right to increase speed and to the left to

decrease speed. |

|

| Figure 9-Control Unit Door |

Figure 10-Control Speed and Direction |

Figure 11-Speed Control Box |

|

|

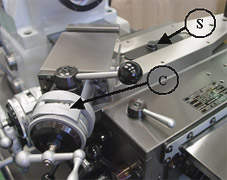

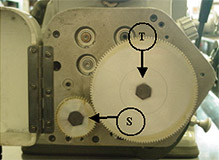

| F.) QUICK CHANGE GEAR BOX |

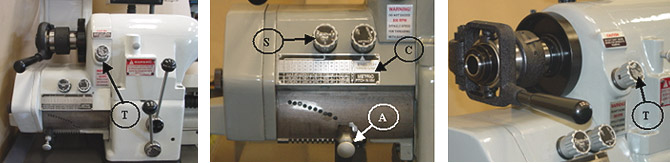

| The Quick Change Gear Box Unit see (Figure 12 & 14), feed or thread

change knob "T", shifted to left is threading, shifted to right

is feed only. The range of threads, their selection and the position

of the knobs for each thread are shown on the chart "C" (Figure

13). Pull out the ball of gear change arm "A" (Figure 13). Then

move arm to left or right, insert in correct position, and change

the selector knob "S" (Figure 13) to 1,2 or 3 position until desired

thread cutting is acquired see (Figure 13). The standard threads

and pipe threads are immediately available through the gear box

by the use of outside change gears (five change gear assembly),

pitches of threads can be cut to 250 threads per inch. |

|

| Figure 12-Feed of Thread Change |

Figure 13-Thread Chart |

Figure 14-Feed of Thread Change |

|

| ※CAUTION:DO NOT SHIFT GEARS

KNOB "T" WHEN THE SPINDLE IS RUNNING. |

|

| G). AUTOMATIC THREAD LENGTH CONTROL |

| When threading into a blind hole or to a shoulder without a thread

relief. The lead screw half nut if engaged at the start of the threading

work is completed. Left or right hand threads are controlled by

Control lever "D" (Figure 15), the lever is joined with the control

bar "B" (Figure 16). When the carriage touches the adjusting screw

"S" (Figure 16) of the length control bar, it will push the lever

"D" (Figure 15) to "STOP" position, and make the lead screw stop.

For method of threading cut, please see Page 10, QUICK ACTING. |

| |

| Figure 15-Control Speed and Direction |

Figure 16-Thread Length Control |

|

|

| H). SPINDLE BRAKE |

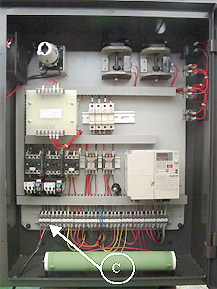

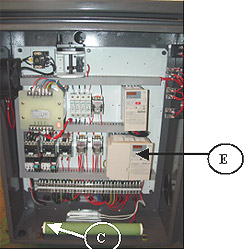

| Inverter unit "E" is used to perform dynamic braking.

In addition, discharge resistor "C" shortens braking time

(Figure 17) |

Figure 17-Control Unit |

|

| I). BELT ADJUSTMENT |

Run spindle at approximately 1000 rpm. Move lever "G" (Figure 18)

to center "STOP" position and let the spindle coast to a stop. This

is done to equalize belt tension. Loosen lock nut "N" (Figure 19)

19mm wrench. Turn adjusting screw "P" (Figure19) 6mm socket head

wrench clockwise to tighten belts. Stop machine and check belt tension,

there should be approx. 25.4mm (1〃) of play in belt.

|

| Figure 18-Control Speed and Direction |

Figure 19-Belt Adjustment |

|

|

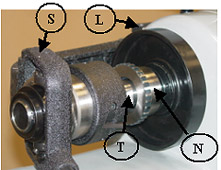

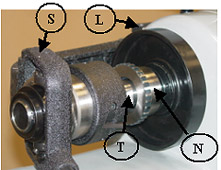

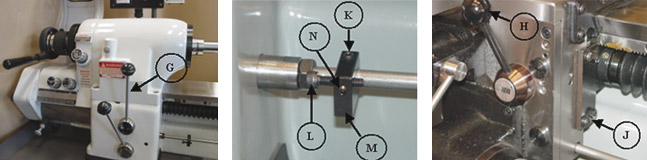

| J). COLLET CLOSER REMOVAL |

| Running the machine with the

collet closer and not having a collet locked in place will damage

the collet closer. Remove the collet closer when using chucks, face

plates, or spindle nose type fixtures. The collect closer should be

removed often for cleaning to prevent loading of chips between collet

closer tube and inside of spindle at rear and collet threads. Removal

method is : Pull out pin”L” (Figure 20). Slide draw tube out of the

spindle. Do not turn the adjusting nut “N” (Figure 20). It is keyed

to the spindle. To remove slide it off the end of the spindle. Do

not remove collet closer by removing screw “S” (Figure 20), this screw

has been adjusted at the factory for proper operation of the collet

closer. |

Figure 20-Collet Closer Removal |

|

K). COLLET CLOSER REPLACEMENT |

| Before replacement of the closer, clean

inside of the headstock spindle and outside diameter at rear of spindle

where Adjusting Nut "N" (Figure 20) is located. Apply a film of light

oil on rear of spindle Do not force Adjusting Nut "N" (Figure 20)

on spindle. If Adjusting Nut "N" (Figure 20) fits to tight, remove

and check for burrs or scratches, then replace. Clean collet closer

tube inside and out apply a film of light oil on slip surface "T"

(Figure 20) of the collet closer tube, replace collet loser and insert

Link Pin "L" (Figure 20). |

Figure 20-Collet Closer Removal |

|

| L). COLLET CLOSER ADJUSTMENT |

- Before using collet closer, and any collet or step chuck to

be used should be thoroughly cleaned.

- Push the lock Pin “E” (Figure 21). To engage lock pin, turn

spindle by hand till lock pin enters notch to lock.

- Press the Closer Adjusting Finger “F” (Figure22) down to the

point “P” (Figure 22).

- Guard “G” (Figure 22) forward with the left hand, and hold the

collet or stop chuck with the right hand at the same time.

- Place a work piece in collet or step chuck.

- Place lever “L” (Figure 22) to the extreme left fixed position.

Turn the Shell Guard "G" (Figure 22) toward operator until the

work piece is clamped by the collet.

- Place lever "L" (Figure 22) to the right, the released position.

Turn Shell Guard "G" (Figure 22) toward operator, move the Adjusting

Finger "F" (Figure 22).

- Test collet closer's tension on work piece. If the work piece

needs additional gripping pressure, press down on the adjusting

finger "F" (Figure 22) and turn Shell Guard "G" (Figure 22) forward

and lock. (see figure 22).

|

|

| Figure 21-Control Speed and Direction |

Figure 22-Collet Closer Adjustment |

|

|

| M). CARRIAGE INDICATING RING |

| Dual dials with Inch and Metric Handwheel dial "W" (Figure 23)

graduations are in 0.01〃 0.2mm. It is built for the operator's convenience

of operation. (Figure 22) Spring loaded indicating ring, just turn

to required location by loosening lock screw "L" (Figure 23) Sliding

cover cage exposes only the dial in use. |

Figure 23-Carriage Indicating |

|

| N). CARRIAGE LOCK |

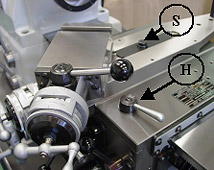

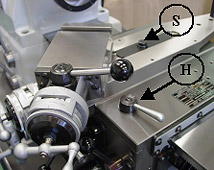

| To hold the carriage in a fixed position on the bed use the Carriage

Lock Handle "H" (Figure 24). Move the lock handle "H" (Figure 24)

clockwise toward the operator, lock the carriage in position. Move

the lock handle "H" (Figure 24) counterclockwise away from the operator.

To unlock the carriage. |

Figure 24-Carriage Look |

|

| O). CARRIAGE CLUTCHES |

The carriage clutches are made of a friction type material, designed

to slip when slide or carriage engages a feed stop. The clutches

are a spring-loaded arrangement and can not be adjusted for more

pulling power. If clutch slips under a cut, it is a sign of improper

tool grinding, dull tool or excessive feed. The friction clutches

have sufficient power to handle all work.

When the machine contacts a feed “stop”, it is intended for the

clutch to slip, To operate clutches as shown in (Figure 25), raise

handle “H” (Figure 25) is approx. 20degress above horizontal, the

clutch will engage, Push down the handle “H” (Figure 25), the clutch

will release. When the carriage lead screw is engaged for threading

the carriage feed clutch is mechanically interlocked (can not be

engaged). This is to prevent machine damage. Adjust clutches as

shown in Figure 25. |

Figure 24-Carriage Look

Figure 25-Carriage Clutches |

|

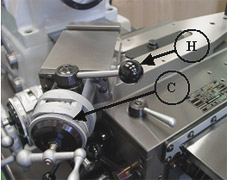

| P). CROSS SLIDE INDICATING RING |

| Dual dials with inch and metric handwheel dial. Each graduation

of the Indicating Ring “C” (Figure 26) is 0.02mm (0.001") on

the diameter. It is provided for operator's convenience. The Indicating

Ring is spring loaded, so a lock screw is not needed. To use it,

just turn the Indicating Ring to required location by hand. Cross

Slide operation of freed and adjustment of clutches are identical

with the operation and adjustment of carriage clutches. If CTL-618EVS

TOOLROOM LATHE needs to be used with the taper turning attachment,

loosen the screw “S” (Figure 26) with a spanner wrench. |

Figure 26-Carriage Look |

|

| Q).QUICK-ACTING TOOL POST COMPOUND SLIDE ASSEMBLY |

| The compound slide has a quick-acting tool post, at the start of

threading cut, place the ball-handle “H” (Figure 21) of the quick-acting

tool post toward the workpiece, at the end of the threading cut,

the threading tool is instantly cleared from the work by hand operated,

handle “H”, for the return of the carriage to the next cut, the

ball-handle lever actuating the tool post slide feed screw. Operate

above procedure repeatedly until the threaded work piece is completed.

Each graduation of the indicated ring “C” (Figure 21) is 0.001”

(0.02mm) on diameter. |

Figure 27-Cross Slide Indicated Ring and Quick Acting Lever |

※ CAUTION :

THE BALL-HANDLE LEVER OF THE QUICK-ACTING TOOL POST MUST BE MOVED

TOWARD OPERATOR AT THE END OF THE THREADING CUT. |

|

| R). POWER FEED UNIT |

The carriage Power Feed unit is mounted on the carriage.

It is powered by a AC motor "M" (Figure 28).

- The power feed can be operated only when the machine is running.

Start the power feed by turning Cam Switch “S” (Figure 29).

- The Cam Switch “S” (Figure 29) controls the direction of the

power feed.

- The carriage Feed Control “N” (Figure 29) controls the rate

of feed. When Cam Switch “S” (Figure 29) is placed in “RIGHT”

position, the carriage will feed toward the right, the cross slide

will feed away from the operator.

- When Cam Switch “S” (Figure 29) is placed in “LEFT” position,

the carriage will feed toward the left, the cross slide will feed

toward operator.

- Turn Cam Switch “S” (Figure 29) to “STOP” position, power feed

motor is turned off.

- The rate of the carriage feed should be pre-selected to suit

each particular job, which depend on material, diameter, type

of cut, and tooling used.

- The numbers on the carriage feed control panel, do not represent

either thousandths per revolution or inches per minute. So the

operator must test sample pieces for determining the spindle speed

and rate of feed which can best suit to the requested surface

finish and production rate, then record the proper settings after

testing.

|

NOTE :

WHEN STARTING INTO PRODUCTION. AN OPERATOR CAN SET THE FEED CONTROL

“N” TO THE RECORDED REFERENCE SETTING, THEN THE SAME TESTED RESULTS

WILL BE OBTAINED. |

|

| Figure 28-AC Motor |

Figure 29-Power Feed Unit |

|

|

| S). COOLANT SYSTEM |

| The coolant pump is controlled by Switch "C" (Figure 30). Turn

Switch "C" (Figure 30) to "ON" position, the pump will run continuously,

turn to "AUTO" position, the pump will run only when the machine

is running. If pump switch is set at "OFF" position, the coolant

pump is off. Sump should be cleaned periodically, depending on the

type of material being machined. |

Figure 30-Control Unit Door |

|

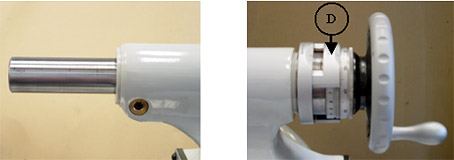

| T).TAILSTOCK |

| The tailstock is mounted on

preloaded ball bearings and can support any load to the spindle. It

is provided with a fine "feed" for accurate work. The spindle of the

tailstock is graduated in eighths of an inch, and 1mm and has a travel

of 95mm (3-3/4〃) The handwheel is dual dial Inch and Metric. Graduations

are 0.02mm (0.001〃). It is built for the operator's convenience of

operation just turn the dial ring "D" (Figure 32) to the required

location. It is unnecessary to tighten the dial rings. They are spring

loaded, so a lock screw is not needed. Sliding cover cage exposes

only the dial in use. |

|

| Figure 31-Tailstock Spindle Travel |

Figure 32-Handwheel Dial Ring |

|

|

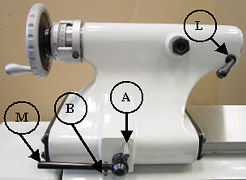

| U). TAILSTOCK SPINDLE LOCK |

| The tailstock spindle lock

holds the spindle securely in any travel position. Move lever “L”

(Figure 33 toward the headstock lock position and backward to the

released position. |

Figure 33-Tailstock Spindle and Body Lock |

|

V). TAILSTOCK BODY LOCK

|

| The tailstock can be clamped

in any position along the bed way by operating Lever "M" (Figure 33).

The Lever "M" (Figure 33) should be adjusted to a clamp position between

the two stop pins "A" (Figure 33) and "B" (Figure 33). When tailstock

is fully clamped, lever "M" (Figure 33) should not contact stop pin

"A" (Figure 33). |

Figure 33-Tailstock Spindle and Body Lock |

|

| THREAD CUTTING |

| CAUTION : DO NOT RUN SPINDLE IN REVERSE WHEN THREADING. |

The CYCLEMATIC CTL-618EVS is designed for rapid and accurate thread

cutting. The quick-change gearbox permits instant selection of 36

different inch and metric threads. Threads can be cut to a shoulder

without running into the shoulder since the automatic stop will

limit carriage travel at a predetermined point in either direction.

Before staring to cut a thread, select the proper cutting speed

for the size of thread to be cut and to give the best finish for

the particular material being used. Maximum recommended threading

speed is 800R.P.M.

Set the quick-change gearbox for desired pitch. To make a selection

on the gearbox thread chart, pull the spring-pressured knob "A"

(Figure 34), out as far as it will go and lower it until it will

move sideways to the desired notch directly under the thread required.

Raise the handle and let plunger drop into hole. If tumbler handle

will not raise far enough to position plunger into hole, loosen

knob "S" (Figure 35), open gear box door and rotate gear "T" (Figure

35), until gears mesh and handle raises, permitting plunger to seat.

DO NOT SHIFT GEARS OR OPEN GEARBOX DOOR WHILE MACHINE IS

RUNNING. |

Figure 34-Headstock and Gearbox

Figure 35-Thread Gearbox

|

Set selector knob "C" (Figure 34), for number corresponding to

left side of gearbox thread chart. Set knob "C" (Figure 34) so desired

number is in bottom position in line with arrow. If the sliding

gear cluster dose not engage the other gears in gearbox properly

to bring the desired number on selector knob "C" (Figure 34) in

line with arrow, loosen knob "B" (Figure 34) open gearbox door and

rotate gear "T" (Figure 35), until gear mesh.

Set Inch/Metric knob "D" (Figure 36), so thread system to be cut

reads at top of knob, If the sliding gear does not engage properly

to bring desired system to read at top, loosen knob "B" (Figure

36), OPEN GEARBOX DOOR AND ROATE GEAR "T" (Figure 37), until gears

mesh and knob is felt to engage detent.

Engage gearbox by turning knob "E" (Figure 36), counterclockwise

in the direction of arrow marked "THREAD" When turning knob "E"

(Figure 36) <THE TEETH OF THE SLIDING GEAR WITHIN THE GEARBOX.>

May not mesh with the headstock spindle gear teeth. If this is the

case, turn headstock spindle with handwheel "F" (Figure 36) while

turning knob "E" (Figure 36) to left until definite click is heard.

Set compound slide at 61 ° and position cutting tool in compound

slide tool post. Position carriage with handwheel so threading tool

is in the center of the part to be threaded.

Carriage control lever "G" (Figure 36), when moved to the left,

will cause carriage to move to the left. When the carriage control

level is moved to the right, the carriage will move to the right.

Carriage travel can be stopped at any time by placing control lever

"G" (Figure 36) in center position. |

NOTE : Carriage power feed unit is not used during threading

operation.

|

| Figure 36-Headstock and Gearbox |

Figure 37-Thread Gearbox |

Place lever "G" (Figure 38) in center position and engage lead screw

nut "J" (Figure 40), by moving ball handled lever "H" (Figure 40)

clockwise. Set two carriage stops "M" (Figure 39) approximately 1/2〃

from both ends of carriage. Loosen screw "K" (Figure 39) to make area

location of stops. Loosen lock screw "N" (Figure 39) and turn stop

screw "L" (Figure 39) to make fine adjustment. With threading tool

away from work toward operator, make a trial run with the carriage.

Pick up the exact relation between the tool and the shoulder or end

of the thread by using the tool post slide. Run carriage to the right,

checking the stop. Make adjustments so tool will clear end of work

by 1/4".

|

| Figure 38-Headstock and Gearbox |

Figure 39-Thread Length Control |

Figure 40-Thread Length Control |

CAUTION : Lock carriage

stops securely before starting to cut the threads. Do not release

carriage nut “J” until threading operation is completed.

With carriage at rest and quick-acting handle "P" (Figure

42), forward in cutting position, feed the desired amount for each

threading pass using cross slide handwheel "R" (Figure

42).

Move lever "G" (Figure 41), to the left and carriage will

travel until it contacts stop at headstock end of machine. The headstock

spindle will continue to run. Carriage stops cause only the gearbox,

lead screw and carriage to stop.

After each pass, withdraw threading tool from work with quick-acting

handle "P" (Figure 42), and return carriage to starting

position by moving carriage control lever "G" (Figure

41), to the right.

LEFT-HAND THREADS can be cut the same as right-hand with the spindle

running “FORWARD” except that cutting pass is made from the headstock

toward the tailstock. Carriage control stops are used for left-hand

threads as well as right-hand threads.

| |

| Figure 41-Headstock and Gearbox |

Figure 42-Carriage and Compound Slide |

|

|

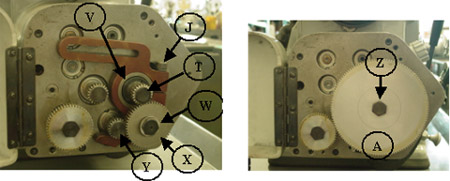

OUTSIDE CHANGE GEARS |

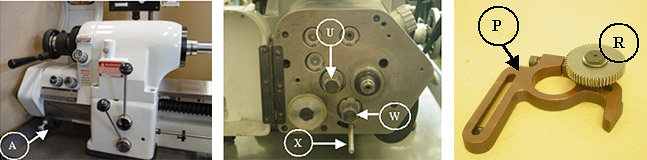

The outside change gears are used to cut threads not provided in

the quick-change gearbox. A set of five gears and a bracket are

supplied as standard equipment with each machine. These gears, when

set up to the gear chart, Figure 45 will cut 10 threads per inch

or 0.25mm pitch according to set up. Three of the gears are shipped

on the bracket and the other two are in place on the shafts as shown

at "U" (Figure 44) and "W" (Figure 44).

BEFORE SETTING UP CHANGE GEARS, PLACE KNOB "A" (FIGURE

43), IN THE "OUT" POSITION.

Fastened to the tumbler handle bracket within the gear box is round

safety bar "X" (Figure 44), that extends out through a slot in the

gearbox plate. This bar is to prevent applying change gears outside

the gearbox until the tumbler handle is placed in the "OUT" position.

Additional gears are available to cut other threads which are not

available through gearbox.

Lubricate bushings and shafts on change gear bracket with spindle

oil each time a setup is made. If long run threading is involved,

lubricate daily. |

|

| Figure 43-Headstock and Gearbox |

Figure 44-Threading Gearbox |

Figure 45-Change Gear Bracket |

|

|

| Inch Threads Using Outside Chang Gear |

- Turn disconnect switch “OFF”.

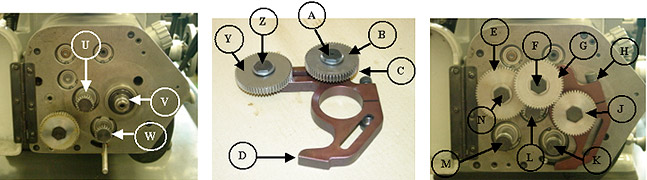

- On inch side of change gear bracket "D" (Figure 50), mount "First

Gear on Stud" "C" (Figure 50) with spacer between gears. Do not

tighten bolt "A" (Figure 50) fully.

- Mount "Idler Gear" "Y" (Figure 50) but do not mesh with "First

Gear on Stud" "C" (Figure 50), or tighten bolt "Z" (Figure 50)

fully.

- Loosen knob “S”(Figure 48), open gearbox door and remove 50

tooth gear "S" (Figure 48), and 127 tooth gear "T" (Figure 48).

Do not misplace key under 50 tooth gear.

- If thread chart specifies number of teeth in "First Gear" to

be other than 22 teeth, remove gear "U" (Figure 49), and replace

with specified gear.

- Remove tumbler gear "W" (Figure 49).

- Mount Change gear bracket assembly, Figure 48, on pivot post

"V" (Figure 49). Do not tighten bracket bolt "H" (Figure 51),

fully.

- Make certain key is in place and mount "Screw Gear" "J" (Figure

51). Replace bolts "K" (Figure 51) and "M" (Figure 51).

- Adjust “Second Gear on Stud” “G”"G" (Figure 51), with 0.08〃-0.010〃

backlash between it and "Screw Gear" "J" (Figure 51). Use plastic

shim stock to help determine backlash. Tighten bolt "F" (Figure

51).

- Adjust “Idler Gear” “E”"E" (Figure 51) with 0.003〃-0.004〃 backlash

between it and "First Gear on Stud" (behind "Second Gear on Stud"

in picture). Tighten bolt "N" (Figure 51).

- Pivot bracket to obtain 0.003〃-0.004〃 backlash between "First

Gear" "L" (Figure 51) and "Idler Gear" "E" (Figure 51). tighter

bracket bolt "H" (Figure 51).

- Make certain all gears are properly meshed and all bolts tightened.

- Close gearbox door, tighten knob "B" (Figure 46), and turn selector

knob "C" (Figure 46) to position specified on chart.

- Turn Inch/Metric knob "D" (Figure 46) to Inch.

- Turn Feed/Thread knob "E" (Figure 46) to "Thread"

- Follow same procedures for setting carriage stops lead screw

nut and compound slide as when cutting threads form the gearbox.

Use of carriage control level "G" (Figure 46), and quick-acting

handle "P" (Figure 47), will also be the same as when cutting

threads from the gearbox.

NOTE :

| (a) |

50 tooth gear “S”, (Figure 48), and 127 tooth gear

“T”(Figure 48) must be remounted (without bracket) to obtain

metric thread pitches through gearbox. |

| (b) |

When disassembling setup, remount 22 tooth gears “U”(Figure

49) and “W”(Figure 49), Figure 5. |

|

|

| Figure 46-Headstock and Gearbox |

Figure 47-Carriage and Compound Slide |

Figure 48-Thread Gearbox |

|

| Figure 49-Threading Gearbox |

Figure 50-Change Gear Bracket |

Figure 51-Mounting Change Gear Bracket |

|

|

Metric Threads Using Outside Change Gears

|

- Turn disconnect switch "OFF".

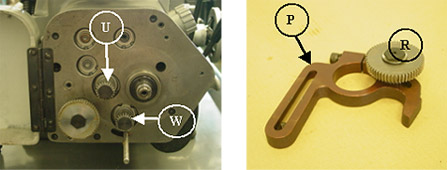

- On metric side of change gear bracket "P" (Figure

56) mount "Idler Gear" "R" (Figure 56). Do

not tighten bolt "S" fully.

- Loosen knob "B" (Figure 52), open gearbox door and

remove 127 tooth gear "T" (Figure 54).

- Mount change gear bracket assembly, Figure 56, on pivot post

"V" (Figure 57), Do not tighten bracket bolt "U"

(Figure 55) fully.

- Remove "First Gear" "U" (Figure 55), and

replace bolt. Do not misplace key.

- Mount "First Gear on Screw" "T" (Figure

57).

- If thread chart specifies number of teeth in "Tumbler Gear"

to be other than 22 teeth, remove gear "Y" (Figure 57)

and replace with specified gear.

- Adjust "Idler Gear" "X" (Figure 57) with

0.003〃-0.004〃 backlash between it and "First Gear on Screw"

"T" (Figure 57). Use plastic shim stock to help determine

backlash. Tighten bolt "W" (Figure 57).

- Pivot bracket to obtain 0.003〃-0.004〃 backlash between "Idler

gear" "X" (Figure 57) and "Tumbler Gear"

"Y" (Figure 57). Tighten bracket bolt "J"

(Figure 57).

- Make certain key is in place and remount 127 tooth gear "A"

(Figure 58). Tighten bolt "Z" (Figure 58).

- Make certain all gears are properly meshed and all bolts tightened.

- Close gearbox door, tighten knob "B" (Figure 52),

and turn selector knob "C" (Figure 52) to position specified

on chart.

- Turn Inch/Metric knob "D" (Figure 52) to "Metric".

- Turn Feed/Thread knob "E" (Figure 52) to "Thread".

- Follow same procedures for setting carriage stop, lead screw

nut and compound slide as when cutting threads from the gearbox.

Use of carriage control lever "G" (Figure 52), and quick-acting

handle "P" (Figure 53), will also be the same as when

cutting threads from the gearbox.

- Observe same operational cautions as when cutting threads from

gearbox

|

NOTE :

| (a) |

50 tooth gear “S”, Figure 4, and 127 tooth gear “T”

must be remounted without bracket to obtain metric thread pitches

through gearbox. |

| (b) |

When disassembling setup, remount 22 tooth “Tumbler

Gear” “W” Figure 5, and 22 tooth “First Gear” “U”. |

|

|

| Figure 52-Headstock and Gearbox |

Figure 53-Carriage and Compound Slide |

Figure 54-Thread Gearbox |

|

| Figure 55-Threading Gearbox |

Figure 56-Change Gear Bracket |

| |

| Figure 57- Mounting Change Gear Bracket |

Figure 58-Mounting 127 Tooth Gear |

|