|

Questions ? Call us at 905-624-5536. |

||||

|

|||||

|

||||||||||

|

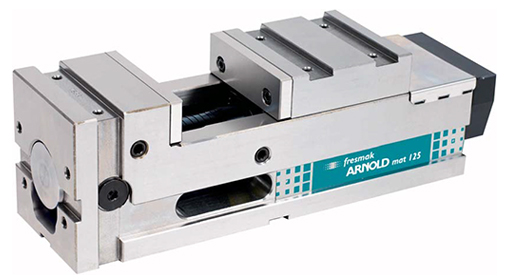

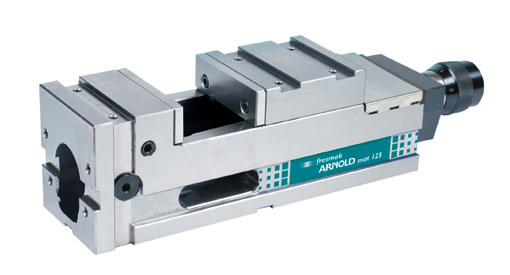

Spanish made quality with repeatability and stability. Arnold MAT series |

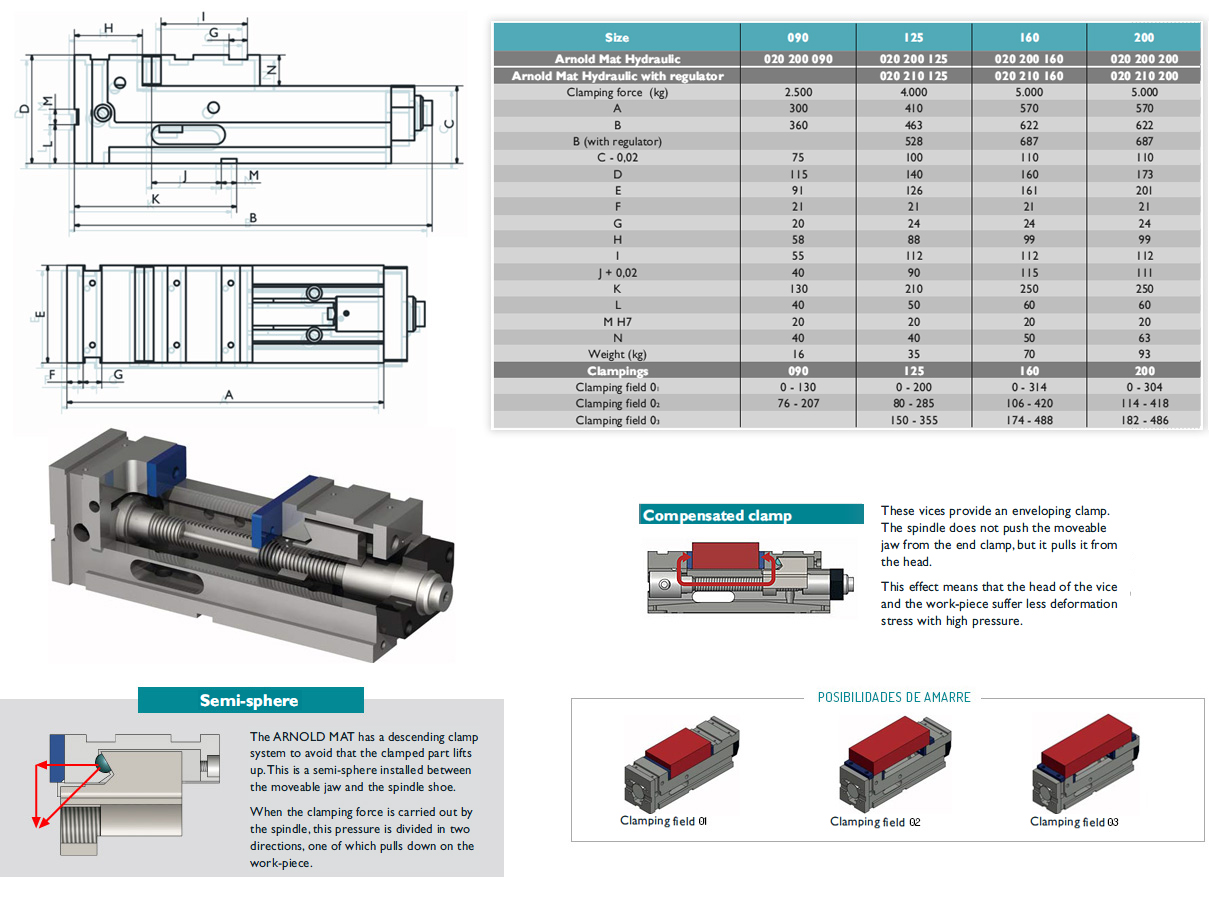

Detailed dimensions

|

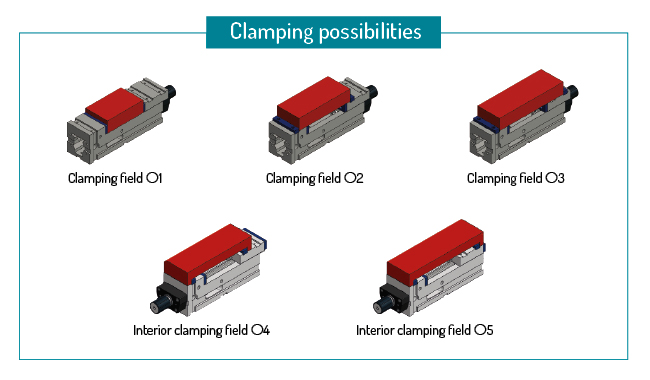

Features Common to all MAT vices High pressure ARNOLD MAT vices maintain their length irrespective of the size of the part, for which they are especially ideal for machining centres (vertical and horizontal). - Accuracy of 0.01 mm (0.0004") in clamping repeatability. - Monoblock design avoids deformations due to high pressure and offers great rigidity and robustness. - Ideal for working in horizontal and vertical machining centres. - Grinding of all surfaces with a parallelism and perpendicularity of 0.02 mm. (0.0008") - Possible working positions: supported on the base, on the side or on the head vertically. - Side windows for quick cleaning of the inside of the vices. - May be clamped to the table either by the four standard clamps supplied or by using four screws located in the body. - Clamping force is 25/40/50 kN, depending on the model. - Two clamping possibilities, either towards the fixed head or the opposite direction. Normal clamping is towards the fixed head. |

||||||||||||||||

|

In addition to the common features noted above each version has unique features noted beside its picture below |

| 1) |

|

1) Manaul Hydraulic Version Features of the Hydraulic version - Built in high pressure hydraulic intensifier. - Power regulator optional. - Angle driver for handle clearance upon request. Standard supply - Base body - Hydraulic spindle - 1 set of plain jaws - 1 handle - 4 end clamps - Instruction manual back to selection table |

| 2) |

|

2) Manual Mechanical - Fitted with a high pressure mechanical intensifier. Standard supply: - Base body - Mechanical spindle - 1 set of plain jaws - 1 handle - 4 end clamps - Instruction manual back to selection table |

| 3) |

|

3) Manual Prox version - Clamping towards the operator for an easier load and unload operation for heavy or oversized workpieces. - Two clamping possibilities of the work piece, either towards the movable jaw or in reverse direction. - The spindle operates at the rear part of the fixed vice head. - Comes with a high pressure hydraulic intensifier. - Angle driver for handle clearance on request. TIPS FOR USE - Should reverse clamping be needed, just place the spindle at the opposite part of the fixed head, clamped by four screws. Then rotate the spindle shoe and the moveable jaw. back to selection table |

| 4) |

|

Arnold Manual Hydraulic with pre-setting pressure regulator. back to selection table |

| 5) |

|

Arnold Manual Mechanical with pre-setting pressure regulator back to selection table |

| 6) |

|

6) Arnold Automatic Hydaulic (Oleo) version - Fitted with a single acting oleo-dynamic spindle, with spring push-back effect. - Rotary connection at the inlet and the outlet for oil. - 4 mm. automatic stroke for closing and opening. - Adjustable clamping force and directly proportional to oil pressure input (see manual). TIPS FOR USE - Should reverse clamping be needed, just place the spindle at the rear part of the fixed head, clamped by four screws. Then rotate the spindle shoe and the moveable jaw. ELEMENTS REQUIRED - Hydraulic unit or single acting 500 bar pneumo-hydraulic pump with vice unit connection hose, pressure control switch, safety valve integrated into the unit and ON-OFF switch. - Pressure gauge. SET SUPPLIED: - Base body - Pneumo-hydraulic spindle - Valve assembly - 1 set of plain jaws - 4 end clamps - Instruction manual back to selection table |

| 7) |

|

Arnold Automatic Pneumatic version requires air supply back to selection table |

| 8) |  |

Arnold Mat Automat - Fitted with a high pressure double acting oleo-dynamic spindle, with spring push-back effect. - 4 mm. automatic stroke for closing and opening. - Adjustable clamping force and directly proportional to oil pressure input (see manual). Tips for use - Should reverse clamping be needed, just place the spindle at the rear part of the fixed head, clamped by four screws. Then rotate the spindle shoe and the moveable jaw. END USER to supply - Hydraulic unit or double effect 100 bar pneumo-hydraulic pump with vice unit connection hose, pressure control switch, safety valve integrated into the unit and ON-OFF switch. - Gauge. back to selection table |

|

| Link to the Fresmak factory web site to see the specs for all their fine products |