|

||||||||||

|

|

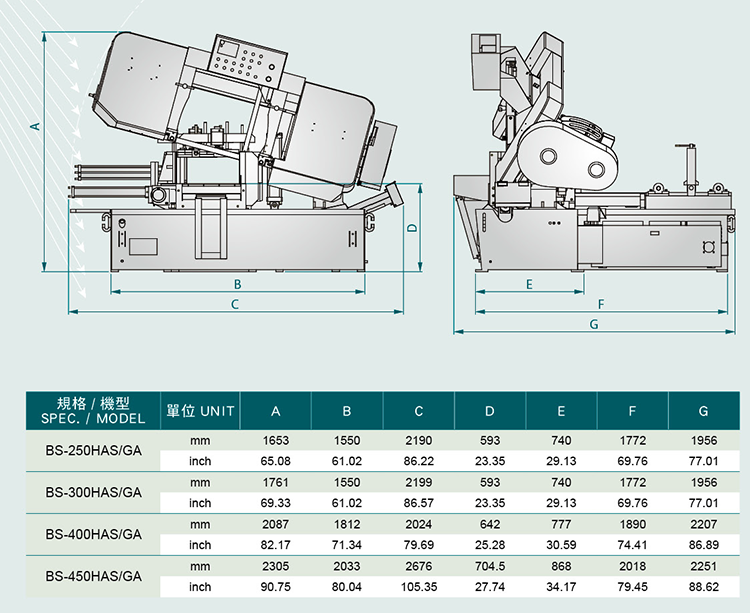

Mega: BS-250-HAS and GA BS-300-HAS and GA 10" and 12" Double Vise Automatic Scissors style horizontal bandsaw. Available with CNC on GA models. |

CNC Option |

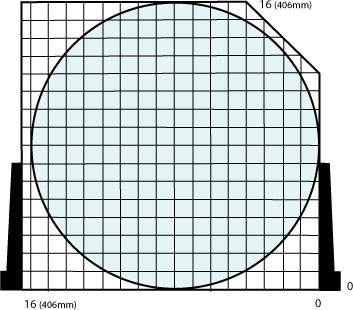

BS-250-HAS |

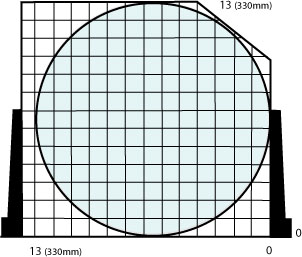

BS-300-HAS |

|

|

| BS-250-HAS / GA | BS-300-HAS / GA | |

| Cutting Capacities | Ø 260mm rect. 300 x 180 rect 280x250> Ø10.23"; 12" x 7" 11" x 10" |

Ø330mm rect. 350 x 250 square 300 x 300 Ø13" rect. 13" x 10" rect. 12" x 12" |

| Bundle Cutting | 200mm x 140mm 8" x 5 1/2" |

250 x 165mm 10" x 6 1/2" |

| Blade Size | 32 x 3660 1.1mm 1 1/4" x 144" x 42 thou |

32 x 3820mm 1 1/4" x 150" |

| Blade Speed | Standard 25, 32, 42, 55, 70, 80 M/min Optional Variable speed 20 - 80 M/min Optional 82,105, 138, 180, 230, 260 F/min Optional Variable speed 65-260 FPM |

|

| Motors | Blade 3 Hp, Hydraulics 1 Hp | Blade 5 Hp, Hydraulics 1 Hp |

| Shipping Volume | 2,040 x ,2012 1,500 80" x 79 " x 60" |

2,110 x 2090 1,600 83" x 81" x 63" |

| Weight Net / Gross | 1,220 /,1440 Kgs 2,685 / 3,190 Lbs |

1410 / 1640 Kgs 3100 / 3600 Lbs |

| Standard features: • Precise cut off length setting. • Auto head-elevation and quick approach control. • Nesting fixture device for bundle cutting. • Cutting piece counter with auto-shut-off. • Multiple stroke counter for long pieces.( Standard 9- Time,) • Power-driven blade cleaning brush and coolant cleaning flush hose. • ldle wheel motion detector. • Carbide and roller blade guides. • Shuttle vise back-jaw feed method.( no need for front stop ) • Unique split machine vise allows cutting to within as little as 2" of bar end automatically.(except HA models) • Unique two-way vise jaw |

Standard Equipment: | |

| • Tools with tool box | 1 set | |

| • 7 ft (2M)long roller table with vertical rollers | 1 set | |

| • Band-Cleaning wire brush | 2 pcs | |

| • Band saw blade | 1 pce | |

| • Instruction Manual | 1 copy | |

| Options: • Automatic chip conveyor. • Variable blade-speed drive. • Variable vise pressure system. • Hydraulic blade tension. • Additional spare roller table, wire brush, saw blade, work-area light, etc. |

||

| MEGA AUTOMATIC HORIZONTAL BANDSAWS QUALITY DESIGN - Skilful engineering and imaginative design give every MEGA Band Saw exceptional cutting capacity. • A completely automatic cutting cycle synchronised with an automatic bar feed mechanism and stock clamping action provide accurate repetitive cutting. • An excellent blade tensioning system and guides keep the blade aligned and under constant load at all times • A hydraulically controlled cutting feed maintains a constant cutting rate regardless of the workpiece cross section. • A power-driven brush continually flushed by a cutting fluid spout keeps the blade and saw guides free of chips for smoother cutting. • A quick approach and normal feed rate selector are equipped to cause the blade to quickly descend into position.| • A "Cutting Piece Counter" is used to preset the number of cuts required during automatic operation. • Two hydraulically operated vises, one a fixed front vise, the other an indexable travelling vise in the rear side. • The hydraulically operated nesting fixture is designed for high production multiple sawing of stacked bars, small rounds and tubes. The fixture contains vertical cylinders mounted on the index and front vises. It holds stacked work firmly to prevent vibration. • A cutting length presetting device is built into the saw to preset the required cutting length of a workpiece during automatic operation. It is simply operated by means of a read-out digital device. • Multiple stroke Preset Counter: when a cutting length of more than 16 is required, the number of strokes can be preset on this counter. The counter is capable of being set to a maximum of nine strokes 144 " SAFETY DESIGN - Every MEGA Band Saw is factory equipped with: • Safety and thermal overload switches. • Well guarded blades and wheel covers. • Saw Blade shuts off automatically when cutting is complete. • Low voltage & zero voltage controls. • A blade breakage sensor/motion detector provides automatic shutoff |

| Features | |

| PRECISE CUT OFF LENGTH SETTING: A convenient digital readout control located at the operator's station provides easy selection of precise bar length requirement. The digital readout is calibrated in 0.10 mm or 0.01 IN increments and can be repositioned without interrupting the cutting cycle. |

|

| AUTO HEAD-ELEVATION AND QUICK APPROACH: Raising the blade higher than necessary to clear the work for the next cut wastes time Head elevation is controlled automatically and no longer requires the operator's attention. A control device that senses the size of the workpiece permits the saw head to raise just high enough so the blade clears the work. This reduces index cycling time significantly. |

|

| NESTING FIXTURE: The hydraulically operated nesting fixture is designed for high-production multiple sawing of stacked bars. small rounds and tubing. The fixture contains vertical cyinders mounted on the index and front vises. lt holds stacked work firmly to assure accurate cuts and prevent center bars from turning. |

|

| CUTTING PIECE COUNTER AND MULTIPLE STROKE COUNTER: The cutting piece counter is used to preset the number of cuts required on automatic operation. When the counter reaches the preset number the saw automatically stops. The multiple stroke counter makes it possible to multiply the number of index cycles when pieces longer than 400 mm (16 in.) are required |

|

| QUICK-ADJUSTING CARBIDE BLADE GUIDES: For the replacement of the saw blade or the repositioning of the guide arms. two levers are incorporated in the saw guides to allow these operations to be carried out quickly and efficiently. (standard on 460/550 models) (optional on other models) |

|

| IDLE WHEEL MOTION DETECTOR: The device not only can protect the saw blade from damage if the blade overloads during cutting. but will also shutoff the machine if the blade should break. |

|

| HYDRAULIC BAND TENSION CONTROL: During operation of the saw, the correct tension is automatically maintained. the tension is reduced when the saw is shut-off This procedure greatly increases blade life. |

|

| QUICK-ACTION HYDRAULIC TWIN-VICE (SPLIT VICE)3-JAW CLAMPING: Materials are firmly clamped on both sides of the saw blade by twin vices. Operating a single switch provides manual or automatic clamping and unclamping materials. These unique twin vices allow automatic bar feed and cutting to within as little as 50 mm of bar end |

|

| UNIQUE TWO-WAY VISE JAW: Both vise jaws on the rear work-carriage are actuated simultaneously, opening or closing, instead of the traditional one that is fixed on one side, moveable on another. This particular design ensures accurate indexing even with warped stock. |

|

| Options | |

| GA NC control |  |

| Automatic chip conveyor A power driven brush keeps the saw teeth free of chips. Rotating screw shaft in the coolant return drains chips of cutting fluid and propels dry chips by auger conveyor out through a discharge chute. |

|

| Variable blade-speed drive. |  |

| Variable vise pressure system. |  |

| Amplifying valve for auto-adjusting cutting feed-rate. |  |

| • Extra long 3.3M Power Roller Table | |

| • Mitre cutting device | |

| • Beam light to show blade cutting line. | |

| ALL MEGA NC cut off machine GA series have been sellers since their introduction For all models input length and number of cuts data into the incorporated microcomputer with the easy-to-use keyboard, and the work pieces will be automatically cut into the pre-set lengths and the required numbers ( up to 9 different courses available ) Special features for all Mega GA series bandsaws: 1. Five-course setting of length & number of cuts. Cut-off length and the number of cuts can be set in five courses by simple key opertion, Total five courses cutting data are shown on the LED display at the same time.The current number of cuts is indicated by blinking signal lights. 2. Automatic kerf loss compensation. The microcomputer permits automatic setting of multiple index including kerf loss in long- length cutting. No need for troublesome calculating procedure. 3. Automatic fault finding ( err, signals ). The sophisticated self diagnosis system constantly monitors the internal state of the computer. Should a failure occur, machine operation will be stopped and the error number of the defective position is indicated. |

|