|

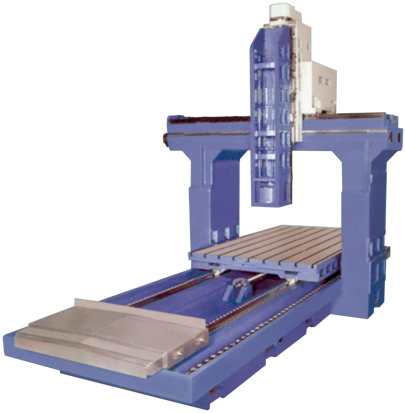

These machines are described as bridge type, double column type or gantry type.

For capacities where Y axis travel needs to about 36" or greater, they offer significant advantages to conventional

machining centers. |

| These machines are available with Anilam, Heidenhain,

Fanuc and Mitsubishi CNC's. |

|

New lager model just announced.

DMC-1725

frame shown to left.

X = 67"

Y = 98"

Z = 36"

#40 or 50 spindle,

71" between

frames |

|

Unique

one-piece casting for the Double Column & Cross Rail design.

Fully supported interface between Double Column and base.

High

and strong base.

Low inertia and high rigidity structure.

X axis slideway mounted on the top of cross rail to shorten the distance

from spindle head to X axis slideway |

|

|

| Fulland now offers 15,000 and 18,000 rpm spindles with

ceramic bearings. These spindles are driven by the Fanuc in - line

direct drive motors and can be serviced by our own staff, without the

expense and delays of returning the entire motor / spindle assembly to

Fanuc in Japan for repair. |

The sizes available have been

expanded since this chart was prepared.

Call us if you

need a larger machine.

|

|

DMC-880 |

DMC-8120 |

DMC-1312 |

| travels |

|

| X x Y x Z |

800 x 800 x 550mm

31.5 x 31.5 x

21.6" |

800 x 1200 x 550mm

31.5 x 47.2 x

21.6" |

1320 x 1800 x 580mm

52" x 47.2"

x 22.8" |

| Z axis - optional longer

travel |

670mm

26.4" |

670mm

26.4" |

700mm

27.5" |

| Spindle nose to

table surface |

110~665mm

4.3 to 26.2" |

With optional 200mm

riser block:

spindle nose to table surface |

310 ~ 895mm

12.2" - 35.2" |

Distance spindle nose to table with optional 500mm riser block |

610 ~ 1165mm

24" - 45.8"

|

| Distance between

columns |

1000mm

39" |

1500mm

59" |

| table |

|

| Dimension |

900 x 800

35.4 x 31.5" |

900 x 1300

35.4 x 51.2" |

1400 x 1000

55.1 x 39.4" |

| Working area |

800 x 750

31.5 x 29.5" |

800 x 1150

31.5 x 45.3" |

1280 x 1150

50.4 x 45.3" |

| T-Slot ( W x No. x

CDv) |

18x7x100 |

18x7x150 |

| Max. table load |

1100 Kg

2420 Lb |

1500 Kg

3300 Lb |

1700Kg

3740 Lb |

| Spindle |

|

| Spindle speed

(Built-in type) |

18,000 standard / 20,000 optional |

| Spindle Motor

(Built-in type) |

18 (optional 21) |

| Torque Max. |

80 (optional 200) |

| Spindle Taper |

HSK 63A |

| Spindle speed

(Direct drive) |

CAT-V or BT-40 12,000 or 15,000 Cat-V or

BT-50

8,000 or 10,000 (Optional) |

| Dual-speed spindle

motor |

| 1. |

Fanuc Alpha T8/ Alpha L15 |

|

ΑT8 7.5 Kw 15000 rpm L:47.7 Nm H:23.9 Nm |

|

ΑL15 18.5 Kw 15000 rpm L:150 Nm H:35 Nm |

|

|

| 2. |

Mitsubishi SJ-VKRS30-06ZM |

|

22Kw-10000rpm L:286 Nm H:8 8Nm |

|

|

| 3. |

Siemens-1PM6138-2LF8 |

|

22 Kw - 10000 rpm L:140 Nm H:53

Nm |

|

|

| Spindle Taper (Opt.) |

HSK |

| Feedrate |

|

| Cutting feed |

1-10,000 (Depending on the CNC fitted) |

| X/Y axis rapid

traverse (opt) |

48,000 mm/min

1890 IPM |

Standard 20,000 Optional 36,000

Standard 780

Optional1420 IPM

|

| Z axis rapid

traverse (opt) |

36,000 mm/min

1420 IPM |

Standard 20,000 Optional 36,000 mm/min

Standard 780 Optional 1420 IPM

|

| X / Y / Z axes servo

motor |

22.4 / 22.4 / 41.5 Kw |

| Linear

guide (Roller Type) |

|

| X / Y / Z axes |

45mm / 45mm / 45mm |

| Ballscrews |

|

| X / Y / Z axes ballscrew

dia x pitch |

50mm x 16mm |

| Z axis ballscrew dia x

pitch |

45mm x 12mm |

| Automatic

Tool Changer |

|

| Type of tool (for

HSK63A) Tool capacity |

Carousel type 12 / 20 (Optional.) |

| Type of tools (for

BT40 BT50) Tool capacity |

Arm type 24/30

Disc type 32 / 40 / 60 (chain type) |

| Maximum tool

diameter |

76mm / 3"

|

| Maximum tool length |

250mm / 10" |

| Maximum tool Weight |

6 Kg 13.2 Lb |

| Tool to tool time |

7 sec |

| Air supply |

6 bar |

| Power supply |

47 Kw |

| Machine weight(net) |

14,000 Kg

30,800 lbs |

14,000 Kg

30,800 lbs |

17,000 Kg

37,840 lbs |

|

| |

DMC-1318 |

DMC-1620 |

DMC-1630 |

| travels |

|

| X x Y x Z axis |

1320 x 1800 x 580

52" x 70.9" x

22.8" |

1600 x 2000 x 700

62.9" x 78.7" x

27.5" |

1600 x 3000 x 700

62.9" x 118" x

27.5" |

| Z axis optional |

700 / 27.5" |

Nil |

Nil |

| Spindle nose to

table surface |

|

110~815

4.3~32" |

110~815

4.3~32" |

| Raising height

200mm |

310~895

12.2" - 35.2"

|

310~1015

12.2" - 40"

|

|

| Raising height

500mm Optional |

610~1195

24" - 47" |

610~1315

24" - 51.7" |

610~1315

24" - 51.7" |

| Distance between

columns |

1500

59" |

1800

70.8" |

1800

70.8" |

| table |

|

| Dimension |

1200 x 2000

47.2" x 78.7" |

1600 x 2200

62.9" x 86.6" |

1600 x 3200

62.9" x

125.9" |

| Working area |

1280 x 1750

50.4" x 68.9" |

1560 x 2000

61.4" x 78.7" |

1560 x 3000

61.4" x

118" |

| T-Slot

(WxNo.xCD) |

18 x 13 x 150mm |

18 x 15 x 150mm |

18 x 22 x 150mm |

| Max. table load |

3,000 Kg / 6,600 lbs |

5,500 / 11,000 lbs |

6,500 / 14,300 lbs |

| Spindle |

|

| Spindle speed

(Built-in type) |

18,000 rpm |

18,000 rpm |

18,000 rpm |

| Spindle Motor

(Built-in type) |

21 Kw |

21 Kw |

| Torque Max. |

200 Nm |

200 Nm |

| Spindle Taper |

HSK 63A |

| Spindle speed

(Direct drive) |

BT40:12,000 or 15,000

BT50:8,000

or 10,000 |

| Dual-speed spindle

motor |

| 1. |

Fanuc Alpha T8 / Alpha L15 |

|

Alpha T8 7.5 Kw~15000 rpm L:47.7 Nm H:23.9 Nm |

|

Alpha L15 18.5 Kw~15000 rpm L:150 Nm H:35 Nm |

| 2. |

Mitsubishi-SJ-VKRS30-06ZM |

|

22Kw-10000rpm L: 286 Nm H: 88 Nm |

| 3. |

Siemens 1PM6138-2LF8 |

|

22 Kw-10000 rpm L: 140 Nm H: 53

Nm |

|

|

| Spindle Taper

Optional |

Cat-V or BT-40

Cat-V or

BT-50 |

| Feedrate |

|

| Cutting feed |

1-10,000 mm/min up to 400 IPM depending

controller) |

| X/Y axis rapid

traverse (o.p.) |

18.000 mm/min |

15,000 mm/min |

12,000 mm/min |

| Z axis rapid

traverse (o.p.) |

18.000 mm/min |

15,000 mm/min |

12,000 mm/min |

| X/Y/Z axes servo

motor |

22.4 / 41.5 / 41.5 NM |

| Linear

guide (Roller Type) |

|

| X / Y / Z axes |

45 / 45 / 45mm |

50 / 50 / 45mm |

50 / 50 / 45mm |

| Ballscrews |

|

| X / Y / Z

ballscrew dia x pitch |

50 x 12mm |

50 x 10mm |

| Z axis ballscrew

dia x pitch |

45 x 12mm |

| Automatic

Tool Changer |

|

Type of tool

(for HSK63A)

Tool capacity |

Disk type 12 or 20 (Optional) |

Type of tools (for

BT40 / BT50)

Tool capacity |

24 or 30 (Disc type); 32, 40 or 60 (chain

type) |

| Maximum tool

diameter |

|

| Maximum tool

length |

250mm

9.8" |

| Maximum tool

Weight |

|

| Tool to tool

time |

7 sec |

| Air supply |

6 kg / cm2 |

| Power supply |

60 KVA |

| Net weight |

21,200 Kg

46,640 Lb |

23,000 Kg

50,600 Lb. |

29,600 Kg

65,120 Lb. |

|

|