|

||||||||||

Cyclematic CP-27 EVS Lathe Electronic Variable Speed Finishing Lathe |

Shown with optional double tool cross slide |

5C collet nose in spindle. Available with compound slide or double acting lever slide. See below.  |

|

|

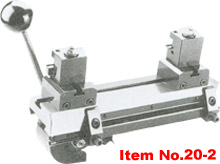

Double tool cross slide The cross slide base provides the needed rigidity when forming, cutting off, or turning with the straight and taper turning slide attachment. The cross slide is easily operated by a hand lever. Two threaded feed stops are provided for fine adjustment of each tool position. Tool No:CHR-68-12 For:CTS-27EVS, Chr-68EVS, CP-27EVS, CTL-27EVS |

|

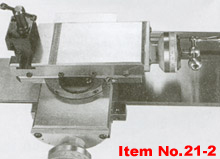

Compound slide The compound slide rest can be readily applied to the CYCLEMATIC Second Operation Machine for screw feed precision turning, facing and boring operations. The large diameter feed screws are hardened and mounted on preloaded ball bearings. The feed screw dials are2" in diameter. Both dials give direct readings in thousandths and are adjustable for Zero settings. Tool No: CTS-27-10 For CTS-27EVS, CTL-27EVS, CP-27EVS |

| CP-27EVS | ||

| Spindle Capacity |

With Chuck | 127 mm 5" |

| With Expanding Collets | 76 mm 3" |

|

| With Round 5C Collets | 27 mm 1-1/16" |

|

| With Hexagon 5C Collets | 22 mm 7/8" |

|

| With Square 5C Collets | 19 mm 3/4" |

|

| With Step Chucks | 27 ~ 152mm 1-1/16 - 6) |

|

| Spindle Nose Diameter | Ø55.5 mm 2.185" |

|

| Spindle Nose I.D/O.D | 5C

(10°) / 4° Taper |

|

| Spindle Speeds (Variable) | 50 - 4000 R.P.M. optionally to 6,000 rpm |

|

| Inverter Spindle Motor | 1 HP |

|

| Hole Through Spindle | 31.75mm 1-1/4" |

|

| Bar stock diameter (5C collet) | Ø27 mm Ø1-1/16" |

|

| Distance Between Centers | No tailstock |

|

| Swing Over Bed | 229 mm |

|

| Compound Slide Travel | Optional X :114 mm / Z :140 mm

|

|

| Coolant Pump | Optional |

|

| Feed Inberter Motor | - |

|

| Tailstock Spindle Travel | No tailstock |

|

| Range of Threads | - |

|

| Net Weight (Approx) | 300

kgs 660 lbs. |

|

| Gross Weight (Approx) | 370

kgs 820 lbs. |

|

| Machine Dimensions (LxWxH) | 1,030 × 970 × 1,670 mm 74" × 34" × 73" |

|

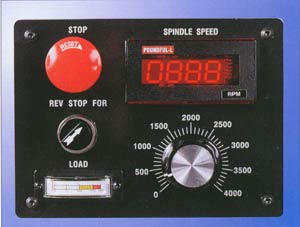

| Standard Equipment / Configuration: - 5-C collet nose with lever operated collet closer. - 1 Hp 230 motor with American made vector drive giving spindle speeds to 4,000 rpm - cabinet base - electronic speed control with LED spindle speed display - hardened steel dovetail style bed - part off slide - compound and cross slide - various toolposts and tooling - digital readout giving constant surface speed - pneumatic collet closers - 6,000 rpm spindle< Optional Equipment / Configurations:| Click here to go to the options and accessories page |