|

Questions ? Call us at 905-624-5536 |

||||

|

|||||

|

||||||||||

| Grob

- toolroom Bandsaws - heavy Duty Plate Saws - friction cutting band saws |

| We have 2 USED Grob saws available now: one 4V18 and one Grob 4V36 and we have some used Grob saw blade welders in stock. |

| HH Roberts is proud to have represented Grob in Canada for 70 years. Our history with Grob dates back to 1953. During that time many hundreds and perhaps thousands (who was counting for that long) of Grob bandsaw and band filing machines were put into service. Grob continues to produce one of the most reliable machine tools we have ever sold. Our thanks to Grob for their support and trust for such a long time. |

| Now available with dynamic braking for new health and safety rules. Can be retrofitted to old saws. Details |

Grob 4V24 Toolroom Bandsaw

|

|

Grob 4V36 Toolroom Bandsaw

|

|

| The most powerful metal cutting vertical band saws in the class. Heavy duty Grob Inc. manufactured transmission with all cold rolled gears and shafts for unequalled strength. Infinitely variable speed range for complete control of your sawing needs. 12" and 20" work heights available, completely manufactured in USA for the ultimate value in metal cutting vertical band saws. | |

Grob Friction Saws

|

Friction Cutting great for stainless steel and other exotics 15 Hp - to 15,000 FPM  36" throat up to 30" work height |

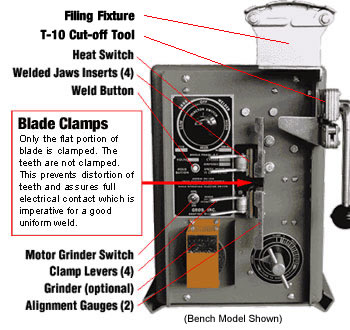

| GROB

Band Saw Blade Welders 1/8" to 1" Carbon steel and Bi-Metal Grob Welders can be supplied as bench models or built into the bandsaw frame. Machine models to fit in the saw column.

|

we have some used Grob welders in stock |

Download the catalog |

|

Steerable air power feed |

Rip Fence |

Mitre gauge |

Circle cutting attachment |

Other options:

|

|