Call us at 905-624-5536

1324 Matheson Blvd E., Mississauga, Ontario, Canada. L4W-2Z7, Fax 905-624-9065

|

Questions ? Call us at 905-624-5536 |

|||||

| H.H. Roberts Machinery Limited: 1324 Matheson Blvd E., Mississauga, Ontario, Canada. L4W-2Z7, Fax 905-624-9065 |

||||||

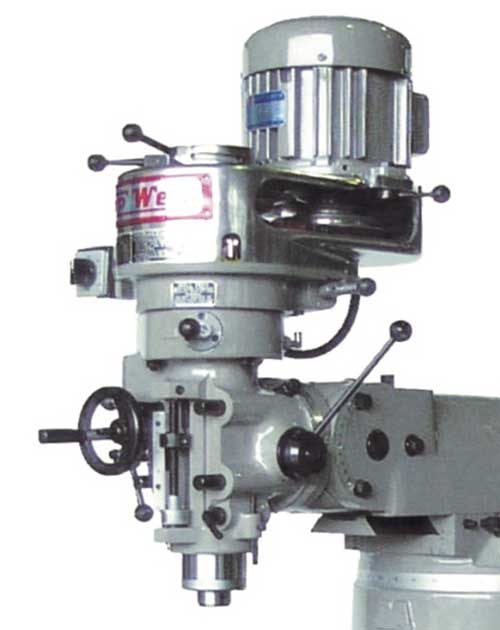

Replacement Milling Machine Heads. |

| Replacement heads for Bridgeport, Topwell, First, Kent, Supermax

and most other Taiwan made Bridgeport clones. If the T-sot in the ram on your

machine has a 6" c/l diameter, these should fit. The variable speed head has a 3 Hp motor, speeds from 60 to 4200. The 3S head has 8 speeds available through belt changing. Both heads are availabe with R-8, # 30 or # 40 taper spindles. We will be stocking the VS version with R-8 and # 40 taper spindles. |

Replacement head on an old Brigdeport Above - the VS series Below - the VA series  |

| variable speed head Model VS |

8 or 16 speed head Model VA |

|

| Quill diameter | 3 3/8" |

|

| Quill travel | 5" |

|

| Spindle motor | ||

| Spindle taper | ||

| Quill power feeds | 0.0381, 0.0762, 0.152 mm / Rev. | |

| Spindle speeds | for a 6,000 rpm head see our Inverter Heads |

optionally 80 - 5,440 16 speed |

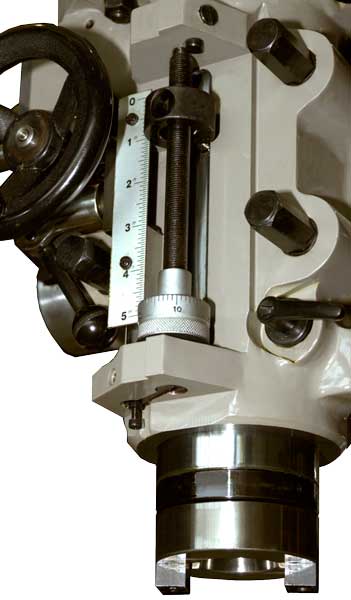

Getting a #40 spindle into a Bridgeport size quill

|

| The two pictures below show standard bearings on an R-8 Bridgeport> type machine on the right. And on the left the 4 bearing set up of Topwell's # 40 spindle upgrade. You can see that there are 2 precision bearings at the bottom or the R-8 spindle and a set of 3 precision bearings on the #40 spindle. Both spindles have a standard bearing up at the top.  |

|

adaptor Drawings and Photos |

|

Bridgeport sized head |

|