|

Questions ? Call us at 905-624-5536 |

||||

|

|||||

|

||||||||||

| We offer 4 different heads for milling machines Three of them will fit Bridgeport mills and most Taiwan made Bridgeport closes. The fourth model is a much heavier head with 5 to 15 hp to adapt to larger machines |

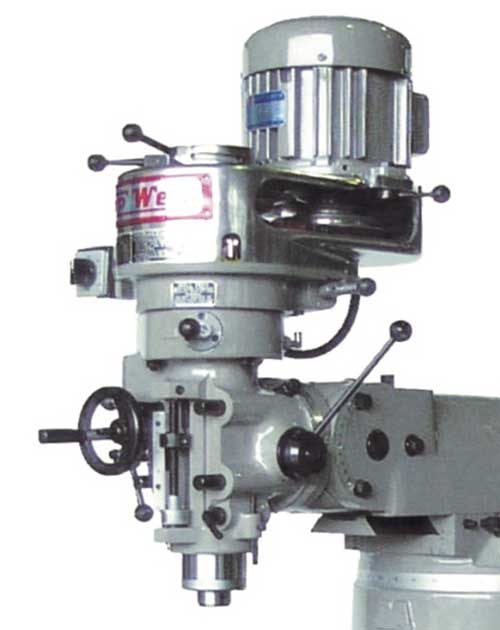

our GL vector drive head on a Bridgeport |

VA 8 speed head |

VS head 3 Hp |

5 - 15 Hp Vector drive head |

| click on a head for more details | |||

| Replacement heads for Bridgeport, Topwell, First, Kent, Supermax

and most Taiwan made Bridgeport clones. If the T-sot in the ram on your

machine has a 6" diameter, these should fit. A complete system. The replacement head will bolt directly onto Bridgeport and all Taiwanese Bridgeport clone rams we have seen. Mount the electronics cabinet on the side or back of the column and connect your power supply. The head is fully wired and ready to go. The back geared heads are most popular because they deliver much more torque at low rpm. Top speed is 6,000 RPM. Use CAT-V-40, BT-40 or NMTBA-40 tools on a Bridgeport format head with increased spindle rigidity. The optional #40 spindle has 3 high prescison P4 spindle bearings at the bottom for extra rigidity. See pictures and explanation below. These heads are ideal for upgrading quill type CNC machines because they can be controlled by most CNCs. We use the same vector drives on our CNC mills and machining centres They can be configured for CNC control of spindle speeds. E stop buttons are now standard as shown on the picture. We now install a circuit to shut down the fan on the inverter motor when the spindle is not running to help a quieter shop environment. Click here to download the heads catalog Click here to download the mounting drawing of the # 4 series heads Click here to download the drawing of the head mount for the heavy 5 / 7-1/2 Hp heads |

|

Cabinet mounted on the side of the column |

Showing a typical electronics cabinet with cooling fan and air filter, relay, and inverter drive. All connections to the head are done. You just need to mount the head on the side or back of the column and have you electrician bring power into the cabinet. |

|

R-8 spindle. # 30, # 40 and Erickson spindles are available. Shown at left is a head with #40 Cat CNC tooling and with the optional power draw bar. The upgraded #40 spindle has 3 sets of 7008 P4 precision spindle bearings whereas most Bridgeport R-8 type spindles have only 2 sets of 7207 P4 bearings. Back geared head give 15 to 750 rpm and 100 to 6,000 rpm Available for 220/1/60, as well as 208, 230 and 460 three phasepower supplies. |

| This is the 5 to 7-1/2 Hp head suitable for fitting to our Topwel, some Hurco, Webb and Kent machines. It is pictured with an Amercian made Hi-Torque power draw bar. Back geared head 15 to 750 rpm and 100 to 6,000 rpm |

|

|

This diagram shows the moving parts in the top half of the GL head. It is in fact a lot like today's modern machining centers with the drive train consisting of 1) the motor shaft and pulley 2) the drive belt 3) the spindle pulley and splined coupling 4) The spindle itself ( not shown ) There are about 85 fewer moving parts. Maintenance is near zero and is normally only a replacement of the timing belt after years of service. The RG verson of the head has a back gear pair. |

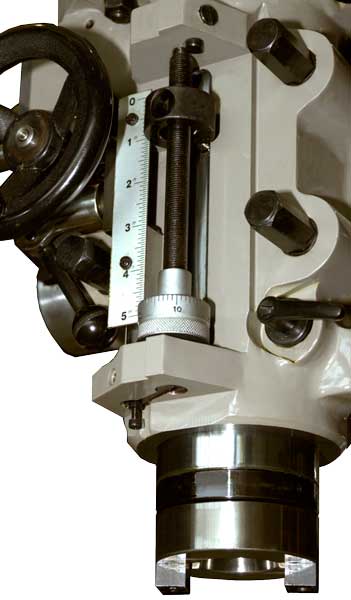

Getting a #40 spindle into a Bridgeport size quill

|

type machine on the right. And on the left the 4 bearing set up of Topwell's # 40 spindle upgrade. You can see that there are 2 precision bearings at the bottom or the R-8 spindle and a set of 3 precision bearings on the #40 spindle. Both spindles have a standard bearing up at the top.  |

|

A shipment of milling heads received into our shop for preparation to sell. |

adaptor Drawings and Photos |

|

Bridgeport sized head |

|